Can reduce weight without appearance defects, SABIC launched special PP foaming compound for automotive interior parts

Latest: Saudi Basic Industries Corporation (SABIC) has launched a dedicated portfolio of PP compounds for foam injection molding (FIM). According to reports, this new mineral enhances PPc F9005, PPc

F9007 and PPc F9015 grades are optimized to improve the appearance of complex geometry automotive interior parts such as door panels, seats, trunk cladding, A/B/C/D pillar covers and center consoles.

Previously, foam injection molding was mainly used for those “invisible” (not easy to see) automotive parts due to the appearance of surface defects such as silver streaks, swirl lines and dents, which limited its application in automobiles .

According to SABIC, the new PP compound can achieve both a uniform high-quality surface quality similar to that of solid injection molded parts, and a significant weight reduction compared to solid injection molded parts, helping to reduce carbon emissions. According to a “cradle to grave” life cycle assessment study (pending third-party review), this material can help

OEMs reduce carbon emissions by up to 15%.

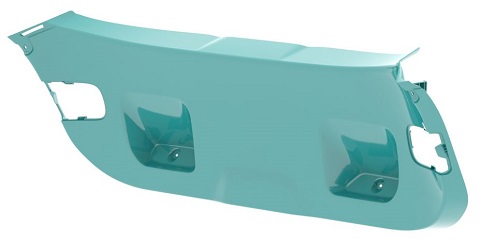

Inner tailgate trim trim using SABIC PPc F9005 foam injection molding

To enhance aesthetics, these grades are currently available in selected vehicle interior colors, as well as custom colors.

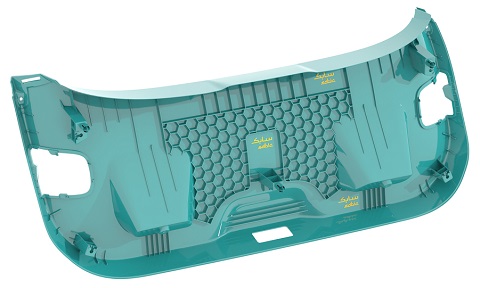

Back of interior tailgate trim

This new SABIC

PP compounds provide a low gloss textured (granular) surface with uniform high quality when foam injection molding, eliminating streaks and swirls. These grades use talc fillers that act as nucleating agents to promote finer air bubbles and help maintain a consistent surface appearance.

On the other hand, according to different types of foam injection molding technology, SABIC

The weight loss effects of PP compounds also vary. For example, when performing “short-shot injection molding”, the same tools as the ordinary injection molding process can be used to achieve a weight reduction of 10%. Weight savings of up to 30% can be achieved when using core-back foam injection molding that requires redesign of parts and tooling.

SABIC’s PP compounds have high flow properties to reduce sink marks and up to 30% weight loss

Both SABIC PPc 9005 and PPc 9015 grades are formulated for foam injection molding and offer moderate stiffness and impact resistance. Foam injection molding can shorten the molding cycle, thereby saving production costs.

In addition, the compound is particularly suitable for use with chemical blowing agents for common foaming process needs. These reagents, in the form of masterbatches, enter the molding machine together with the plastic pellets and activate the released gas for foaming during the melting stage.

To advance the development of polymer foaming processes, SABIC has established a Foaming Innovation Center. The center is equipped with foam processing and analysis equipment, enabling the company to develop more foam solutions.