Dimethyltin Dichloride/CAS 753-73-1

Dimethyltin Dichloride/CAS 753-73-1

Overview:

Product Name: Dimethyltin Dichloride,CAS 753-73-1,Dimethyltin Dichloride,Dimethyltin Chloride,Dimethyltin Dichloride 50% Aqueous Solution,Dimethyltin Dichloride

Product code: DMTC

Chinese name Dimethyltin dichloride (DMTC)

CAS No. 753-73-1

English name Dimethyltin Dichloride

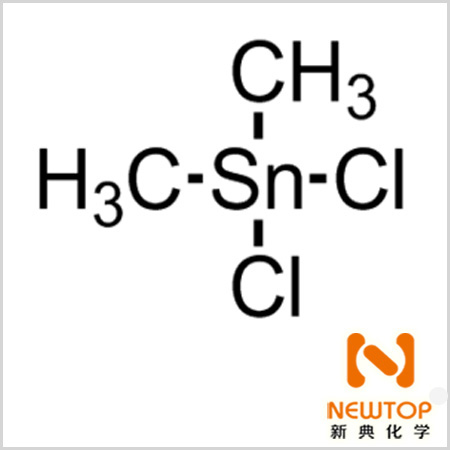

Chemical formula C2H6Cl2Sn

Melting point 107-108

Hazardous Description Hazardous

Storage Temperature Below 30°C

Basic Information

English name: Dimethyltin Dichloride (DMTC)

CAS No.: 753-73-1

Molecular formula: C2H6CL2Sn

Chinese name: Dimethyltin dichloride

Synonyms: Dimethyltin; Dimethyltin dichloride, 98%; Dimethyltin dichloride; Dimethyltin chloride; Dimethyltin chloride

Dimethyltin dichloride, Dimethyltin chloride; Dimethyltin dichloride (standard)

Dimethyltin chloride; Dimethyltin dichloride 100G

English name: DIMETHYLTIN DICHLORIDE

English Synonyms: DMTC50%; dichloriddimethylcinicity; dichlorodimethyl-stannan

Dimethyldichlorostannane; Dimethyltindichloride,min.95%; Dimethyldichlorostannane; Dimethyltindichloride,min.95%; Dimethyldichlorostannane

DIMETHYLSTANNOUSCHLORIDE;DICHLOROMETHYLSTANNANE; DIMETHYLDICHLOROMETHYLSTANNANE

DIMETHYLDICHLOROTIN: 50% IN WATER

Production Method:

Molten metallic tin reacts with chloromethane under the action of catalysts such as tetramethylammonium chloride, and is produced by refining.

Toxicity: moderately toxic.

Emergency treatment method

Emergency treatment for leakage

Isolate the leaking contaminated area, set up warning signs around it and restrict access. Emergency personnel wear gas masks (full face mask) and gas suits. Collect carefully, place in plastic bag, seal and transfer to safe place. Soak the collected residue in dilute alkaline water, recycle and collect the generated solids and send them to the production plant for disposal.

Uses:

White crystals.

Used in the production of PVC heat stabilizer, TCO photovoltaic glass, LOW-E glass coating raw materials, medicine, esterification reaction catalyst.

Mainly used in Low-E glass coating materials, glass bottle hot end spray coating, esterification reaction catalyst and other fields.

Storage and transportation:

Transportation: loading and unloading should be light, packaging breakage should be prohibited during transportation, and should be sealed immediately when found broken, trace leakage should be diluted with large amount of alkaline water;

Packing:

Packing: it is advisable to use glass containers, plastic containers, chlorine corrosion-resistant metal utensils to contain, sealed and stored. Store in a cool, dry place, keep the container sealed, avoid contact with oxides. Do not inhale dust, avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothing separately and wash before use. Maintain good hygiene practices.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

sales@newtopchem.com |

Telephone: |

86-152 2121 6908 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |

Our Company

Since its establishment, the company has adhered to the service tenet of “integrity-based, customer first”, adhered to customer demand as the focus, market-oriented, adhered to technological innovation, management innovation and service innovation, and constantly implemented lean production, refined management, to provide customers with better products and services! The company has its own factory, research and development base, set up a strict scientific quality management system, and constantly committed to technological innovation, product innovation and management innovation, so as to ensure that our products have a certain competitiveness in the same industry. The factory is located in Jining City, Shandong Province, China, covering an area of 500 acres, and the current production capacity of various types of amines is 5,000 to 10,000 tons per year.

Our Advantages

Strict Quality Management

Our company strictly implements ISO9002 quality management standards and has established a complete quality management system to ensure the long-term stability of product quality.

Efficient Service

Our production is efficient and reliable, so we deliver on time and within delivery deadlines. At the same time, our team is always happy to help customers and strive to solve customer problems in a short time.

Competitive Price

We have long-term services in wholesale Polyurethane catalyst and have established long-term and stable cooperative relationships with many retailers and agents to provide our customers with reasonably priced products.

OEM Available

Our employee team has high R&D capabilities, superb design and development capabilities, skilled manufacturing technology, and rich product application experience, and can also meet OEM business needs.throughout the entire industry chain.