In the era of lightweight automobiles, let’s see how high-performance NORYL™ materials can make a difference

Latest News:Environmental sustainable development is the common goal pursued by the global society, and all walks of life are working hard for it. For the automotive industry, energy conservation and emission reduction are an important way to achieve environmental protection goals, and vehicle lightweighting is an important measure to achieve automotive energy conservation and emission reduction.

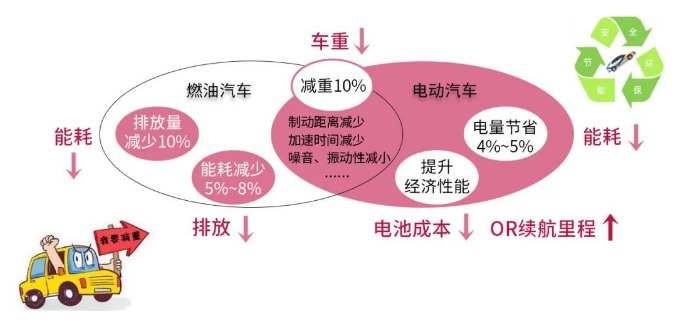

According to the law of conservation of energy, the heavier the object, the greater the driving force required, and the corresponding energy consumption is more. It is estimated that for every 10% reduction in the quality of the car itself, the energy consumption of fuel vehicles can be reduced by 5% to 8%, and the emissions can be reduced by 10%; the power consumption of electric vehicles can be reduced by 4% to 5%, and the cruising range can be improved. At the same time, the lighter weight of the car will also bring advantages such as reduced braking distance and acceleration time, and reduced noise and vibration.

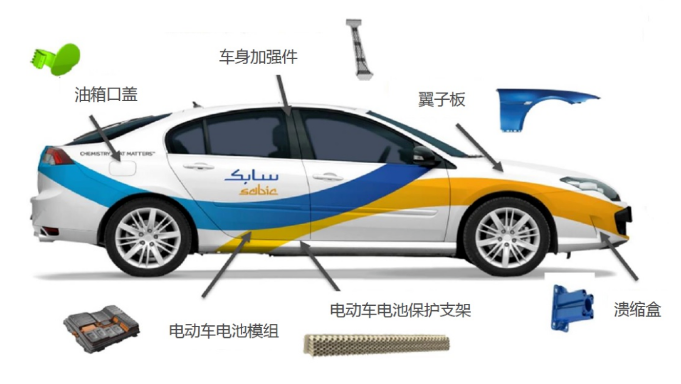

Lightweight automobiles have become an important development direction of the industry in the future. Compared with metal materials, plastics have the advantages of low density and high cost performance, and have gradually become the main choice for lightweight vehicles. The NORYL™ product series developed by Saudi Basic Industries Corporation (SABIC) can be applied to important components such as automotive exteriors and electrical equipment, providing a new solution for automotive lightweighting.

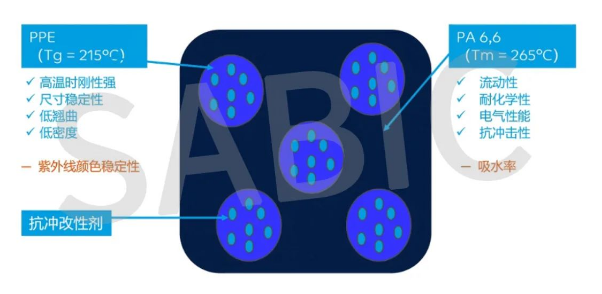

The NORYL GTX™ series is a member of the NORYL™ product family, a high-performance alloy compounded from two incompatible polymers, PPE (polyphenylene ether) and PA (nylon). NORYL

GTX™ material fully integrates the properties of PPE and PA materials, supplemented by impact modifiers, and effectively utilizes the advantages of amorphous and crystalline properties to form a heat resistance, chemical resistance, high flow, good size High-performance materials with characteristics such as stability, low density, and impact resistance, currently have two types of conductive and non-conductive products to meet different types of application needs.

● Application 1: Automotive Electrical Equipment

Automotive electrical equipment includes power supply system, electrical equipment, power distribution device and whole vehicle circuit. Due to the particularity and importance of automotive electrical equipment, the requirements for materials are relatively high in terms of processability, dimensional stability, and heat resistance.

In the extreme environments of automotive applications such as cold, heat and humidity, NORYL

GTX™ material can maintain good mechanical properties, with balance, excellent dimensional stability, high fluidity, low shrinkage processability, etc., so as to achieve thin-walled design with reduced weight, meet the needs of automotive electrical equipment, and can be applied to electrical boxes, relay boxes, distribution boxes, connectors, etc.

● Application 2: Automotive Exterior Parts

Automotive exterior parts are the part systems that use the most plastic materials in auto parts, and have certain requirements for material durability and dimensional stability. NORYL

GTX™ products have a lower coefficient of linear expansion for improved dimensional stability and improved clearance and flush management. Under high temperature and humid conditions, it has a high level of electrical conductivity, good in-line spray performance, etc., while maintaining excellent mechanical properties.

Compared to parts made of metallic materials, NORYL

GTX™ resin can reduce vehicle weight by at least 3.2 kg, energy consumption by 40%, and carbon dioxide emissions by 42%, achieving energy saving and emission reduction. In injection molding, the mold cost is also reduced, and it can be applied to exterior parts such as fenders, fuel tank covers, and corner panels.

As a high-performance alloy material, NORYL GTX™ materials can provide filled and unfilled material solutions for various automotive applications, and are widely used in various automotive related components. Compared with other similar materials, NORYL

GTX™ products have lower coefficients of linear expansion and are better suited for larger parts.

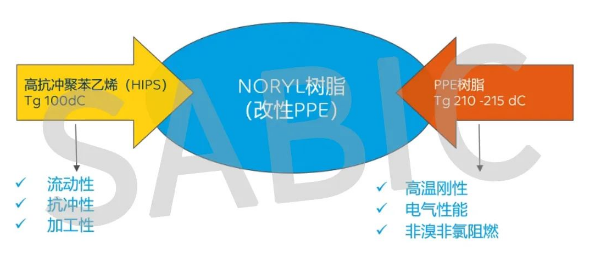

NORYL™ resins are fully compatible blends of PPE (polyphenylene ether) and HIPS (high impact polystyrene). NORYL™ resins fully integrate the properties of PPE and HIPS materials to form high-performance materials with high fluidity, high impact resistance, ease of processing, high temperature stiffness, and low dielectric constant/dielectric loss.

With the development of the automotive industry, especially the growth of electric vehicles, the battery size is getting larger and larger. How to reduce the weight of the battery, protect the battery from collision, and improve the safety of the battery has become a problem that needs to be solved in the plastic solution. NORYL™ resin products delivered their answer.

Under the same injection molding process, PA66 requires a thicker wall thickness to achieve and maintain low warpage, which is not conducive to achieving the goal of lightweight batteries. NORYL™ resin has the characteristics of low density, resistance to electrolyte and hydrolysis, non-bromine and non-chlorine flame retardant, dimensional stability, etc. It can also meet UL9 in the case of low wall thickness

The flammability rating of V-0 facilitates design simplification, product weight reduction, fastener-free, thin-wall flame retardant, durable and cost-effective battery packaging.

As environmental sustainable development has become a global social consensus, vehicle lightweighting has become a major measure to reduce vehicle energy consumption and pollutant emissions. Among them, the weight and performance of materials are crucial to the realization of lightweight vehicles. Because of its high performance, low specific gravity, and simple molding, plastics are increasingly used in automobiles.

As a senior practitioner in the plastics industry, Nagase has joined hands with the special materials business of Saudi Basic Industries Corporation (SABIC) to provide automotive companies with lightweight solutions, meet the special needs of automotive manufacturers for parts, and help them achieve their lightweight goals at the same time. , reduce processing costs, improve design flexibility and operational safety, and promote the innovation and development of the automotive industry.